EU GMP Annex 1: Full compliance with MAS-100 Iso air samplers »

MICROBIAL AIR SAMPLER MAS-100 Iso MH®

HIGHEST GERM COLLECTION EFFICIENCY AND SAFETY IN ISOLATORS AND RABS WITH UP TO FOUR SAMPLING POINTS

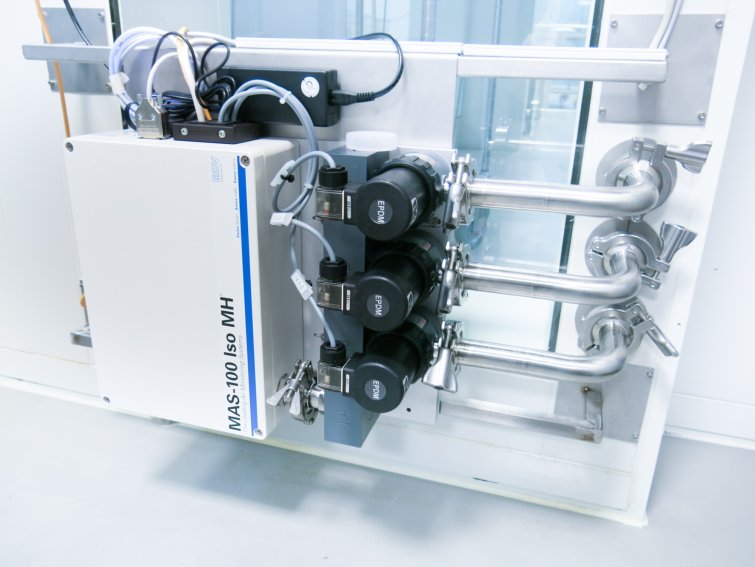

The microbial air sampler MAS-100 Iso MH is used for microbial monitoring of air in isolators and RABS. It can be configured with 1 - 4 sampling heads. The sampling heads with the agar plates are located in the containment, while the control unit with electronics and all moving parts is located outside the enclosure and aspirates the air through a pipe/tube system. The system is designed for maximum protection of the product and the environment and can be controlled fully automatically via various data interfaces.

- Developed according to GAMP 5, fully validated according to ISO 14698 and EN 17141

- Compliant with EU GMP Annex 1 requirements

- Can be used in environments of ISO 14644 cleanliness class 5 / GMP Grade A

- 1 - 4 sampling heads with a single space-saving base unit

- No moving components (e.g. blower) in the containment

- Sequentially activated double valve protects the containment from contamination ingress

- If necessary, the base unit can be replaced during operation as one valve is still sealing the air duct

- All components in the enclosure are made exclusively of stainless steel

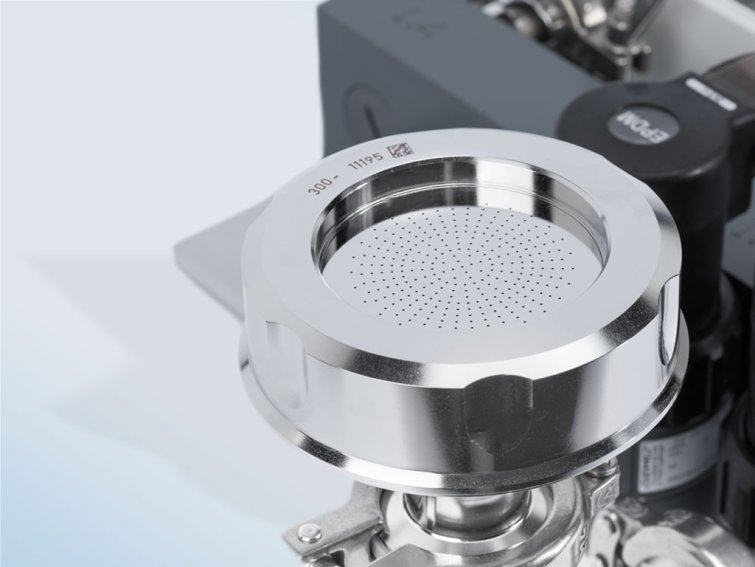

- Precision seal without sealing ring between perforated lid and sampling head facilitates cleaning and disinfection

- Disinfection cycle with vaporized or gaseous hydrogen peroxide can be started automatically or manually

- Optional installation of environmental protection filters for the processing of highly active substances

- Specified for pipes/tubes from collecting head to control unit up to 10m length, tested up to 50m

- Compatible with many different agar plates e.g. 90mm Petri dishes, Growth Direct® plates

- Interchangeable and sterilizable perforated lid

- Integrated mass flow sensor with temperature and pressure compensation for ambient air sampling

- Air flow can be calibrated independently with digital anemometer

Pharma

![]()

Engineering

![]()

Hospital & Medical Products

![]()

FREE AND NON-BINDING OFFER

GET AN OFFER NOW

We will be happy to provide you with an offer tailored to your needs. Please fill out the following contact form. We will get in touch with you as soon as possible.

TECHNICAL SPECIFICATIONS

- 1 to 4 sampling heads per control unit

- Air flow rate 100 standard liters per minute (SLPM)

- Accuracy of air flow ±2.5%

- Physical cut off diameter d50 = 1.1um with standard perforated lid 300x0.6mm

- Sampling head made of stainless steel EN 1.4435 (X2CrNiMo18-14-3) according to BN2 (electropolished pharmaceutical grade) with surface roughness RA < 0.8µm

- In-line decontamination of the sampling head and the air aspiration channel

- IP 65 protection as a standard

- Length of base unit 38cm, width 23cm, height 12cm, weight approx. 7.5kg (without sampling heads)

- Specified tube/pipe length from sampling head to electronic unit of 10m, tested up to 50m

- Operation with 90-100mm agar plates

- Fully automatic calibration of air flow with MAS-100 Regulus digital anemometer

Software

- Computer-based software for configuration, qualification and calibration

- Integration into SCADA system or similar control systems

- Adjustable 'out of specification' air flow limit selectable between 2.5% and 25%.

- Ethernet, Profi-Bus, ProfiNet adapter, USB, 9 digital inputs/outputs.

- Sampling programs: Standard, sequential and consecutive

- Comprehensive documentation of data interfaces

- Calibration reminder with the option to lock the instrument when the calibration interval has expired

SCOPE OF DELIVERY

- MAS-100 Iso MH base unit

- Adapters and seals for data cable connections

- Calibration certificates for air sampler and digital anemometer (issued by own ISO 17025 accredited calibration laboratory)

Depending on individual order:

- 1 to 4 external valves and control cables

- Valve block for instruments with 2-4 sampling heads

- Mounting plate for base unit and valve block

- Stainless steel perforated lid (standard: 300x0.6)

- Stainless steel agar plate holder (Easyclean or standard)

- Network module (Ethernet, ProfiNet, Profibus)

- Tri-Clamp

- Silicone seal with or without protective mesh

- External power supply with power cable and region-specific adapters

- Stainless steel dust cover

EU GMP Annex 1

The microbial air sample MAS-100 Iso NT fully complies with the requirements of EU GMP Annex 1. If the viable air samplers are additionally combined with settle plates for passive monitoring, all requirements related to environmental monitoring and contamination control strategy (CCS) as specified in Chapter 9 "Environmental and process monitoring" can be met. Companies that choose MBV products for their isolators and RABS therefore comply with the requirements of Annex 1.

SAFETY ABOVE ALL

Product protection is ensured by the complete separation of the sampling head inside the containment from the outside base unit with the control electronics, the blower, the flow sensor and the components for disinfection with hydrogen peroxide.

A sequentially activated double valve prevents the ingress of contaminants. All surfaces in the containment can be automatically sterilized with gaseous or vaporized hydrogen peroxide. Filters can also be installed to protect the environment and operators from highly active substances.

PERFORATED LIDS: FOUNDATION FOR MAXIMUM COLLECTION EFFICIENCY

The precision, robustness and material design of the perforated lid have a decisive influence on the collection efficiency and long-term stability of the measurement results. That is why we place the utmost importance on the uniformity of the holes, the accuracy of fit of the lid/instrument sealing surface and the ease of manipulation of the sampling lid - even when wearing gloves. The lids can be freely interchanged between instruments. This allows one unit to be used while another lid is being autoclaved.

calibration

All results of active microbial air samplers depend on correct air flow and air volume. That is why we ensure that the calibration of our instruments can be traced back to international standards via the certified MAS-100 Regulus digital anemometer and via our ISO 17025 accredited calibration laboratory. Each step in this cascade is fully documented, giving you the confidence to produce reliable results every time.

To the digital anemometer MAS-100 Regulus »

To our calibration service »

FAQ - frequently asked questions

Find answers to the most frequently asked questions about the MAS-100 Iso MH here.

Service and Support

Even the best product needs the best service to ensure that it functions perfectly and reliably at all times. As your partner in microbial air monitoring, our service team accompanies you throughout the entire product life cycle. Whether calibration, adjustment, support for applications or repair - high quality and your satisfaction are our top priority.

GOOD TO KNOW

IMPACTION PRINCIPLE in microbial air sampling

For active microbial air sampling based on the impaction principle, a predefined volume of air is drawn through a perforated sieve. The air and the particles in it are accelerated and directed onto an agar plate positioned below the sieve.

Due to inertia, particles above a certain size are impacted onto the agar medium. After appropriate incubation, microbe-bearing particles become visible as colony forming units (CFU), can be counted and reported as CFU/m3. The particle size at which 50% of the particles impact and the other half remain in the air stream is called the cut off diameter d50 (um).

Great emphasis is placed on precision in the manufacture of MBV perforated sieves. This ensures that the cut off diameter is identical in all holes and that microbial air sampling is repeatable.

FROM EXPERTS FOR EXPERTS

Downloads

BROCHURE

"EXPECT NOTHING" – Everything about MAS-100 Iso air samplers

APPLICATION NOTE

Isokinetic microbial air sampling on MAS-100 instruments

APPLICATION NOTE

Safe remote microbial air sampling with MAS-100 Iso MH

BROCHURE

"Precision in your hands" - All about the digital anemometer MAS-100 Regulus

EXPERT VIEW

Our CEO Ronny Zingre in the EPR – about active air monitoring in aseptic fill/finish isolators

ARTICLE

How can aseptic manufacturers prevent losses in the millions?

ARTICLE

The critical role of active viable air sampling for Annex 1 compliance

INSTALLATION

Download the installation checklist for MAS-100 Iso MH

ANY QUESTIONS?

Our expert Andy Zingre will be happy to assist you. We look forward to hearing from you.